By Maciej Kuczynski

Collaborative robots that can work safely in the same environment with people have an important role in enabling flexible manufacturing and creating a competitive advantage. A new generation of ‘cobots’ is emerging as the evolution of classical industrial robots in response to the needs of Industry 4.0. In applications where flexibility is key, opposed to maximum production speed, collaborative robots are now filling the gap in the robotics market with their extremely user-friendly software tools and integrated sensory functions, which now include machine vision systems, location capabilities and integration with warehouse systems.

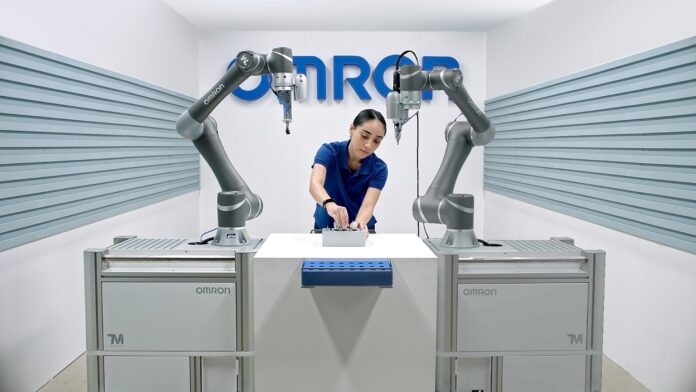

Collaborative robots are gaining strength. Although lightweight, for example, the Omron Techman TM14M robot can lift goods up to 14kg. While compliant with the ISO 10218 safety standard, which describes the interaction of robots and humans, industrial collaborative robots are now becoming actual team members in production and logistics environments thanks to their lifting capabilities. This brings innovation to the factory floors through true harmonisation and collaboration of humans and machines.

Collaborative robots can be deployed in a wide range of applications, such as production, testing, quality control, packaging and palletizing, as well as intralogistics. For example, it is possible to support people in assembly processes at those stages where precision and repeatability are key. These robots can apply adhesives and seals with simultaneous quality control. Thanks to repeatability, they are also perfectly suited for automating complex quality tests. Being able to do heavy lifting, they can also be used as palletizers, with proper safety equipment.

The new generation of collaborative robots can be easily integrated with mobile robots. This cooperation is made more accessible thanks to the low weight of the latest robots, as well as the possibility of building mobile platforms on mobile robots, such as Omron LD autonomous intelligent vehicle. Collaborative robots can now be a natural part of a flexible, constantly evolving production environment in which the re-deployment of machines, line changeovers and conveyors are needed.

Collaborative robots installed on, for example, mobile robots can become elements of innovative logistic solutions and provide complete sub-assemblies and semi-finished products for assembly stations, and finished products to be placed in stock or quality control stations. Currently, collaborative robots can effectively complement and augment people’s work in many discrete manufacturing processes.

Collaborative robots are just beginning to enable innovation and competitiveness at manufacturers. High versatility, a wide range of possibilities including the ability to carry out tasks performed so far only by standard robots, all easily configurable by local engineering staff, are undisputed advantages of cobots.

If we additionally consider a much easier implementation resulting from the reduced need to provide typical robots security measures and incomparably greater flexibility of operation, the return on such investment can be very positively surprising. Therefore, the forecasted increased share of robots cooperating of the total number of industrial robots should not come as a surprise.

Omron and Techman Robot Inc., the world’s leading company for collaborative arm robots that work together with people, recently signed an agreement to form a strategic alliance in the area of collaborative robots.

Omron and Techman will provide collaborative robots that can be used for a wide variety of applications such as electronics assembly, product testing and inspection. These robots will enable flexible manufacturing and increase the productivity and quality of production lines for customers in the automotive and electronic industries, as well as various material handling operations within a broad range of manufacturing industries, to realize an innovative manufacturing environment where humans and machines work in harmony. – GeekWire.co.za

Maciej Kuczynski is the Regional Marketing Manager of Omron Electronics